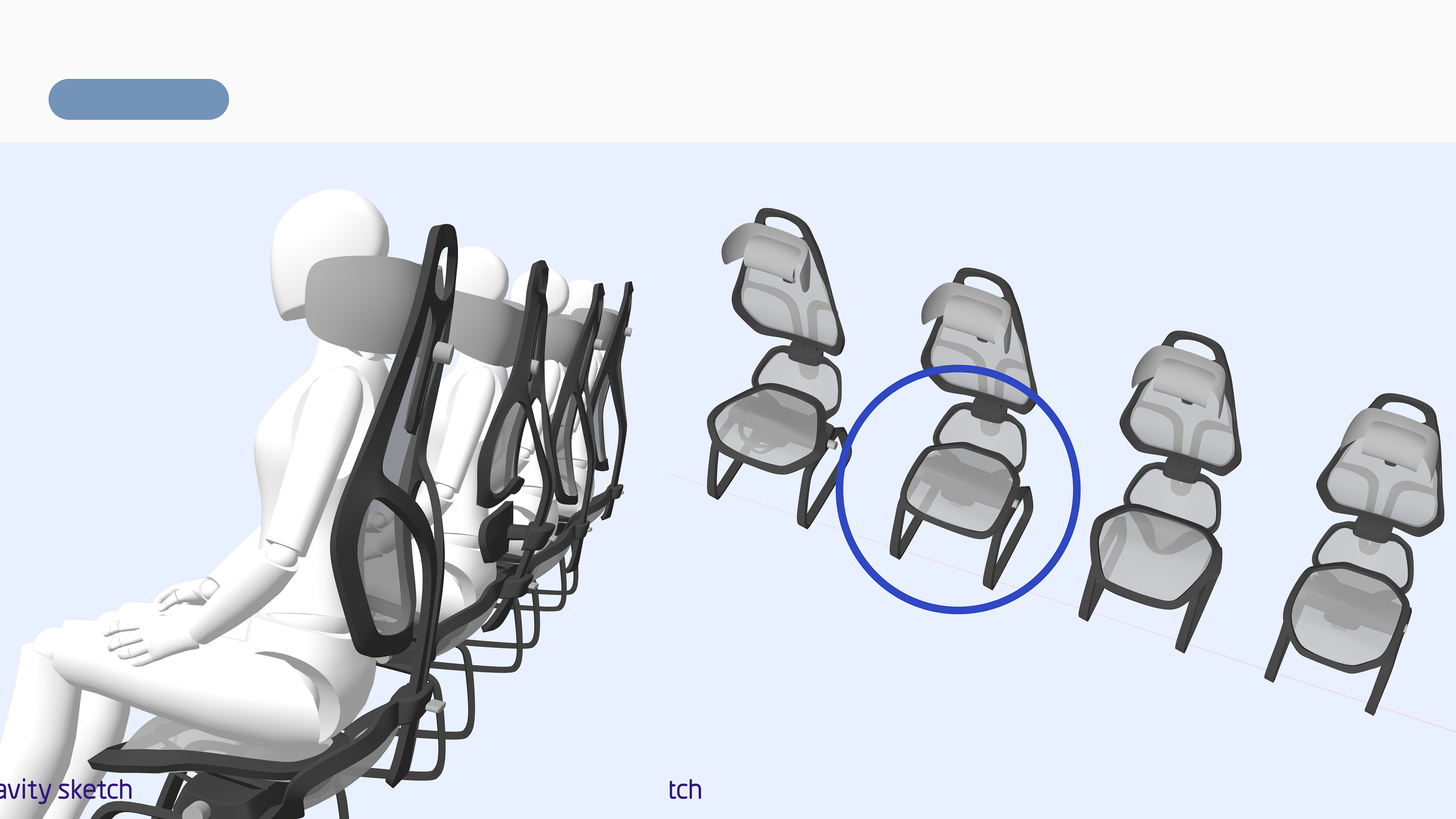

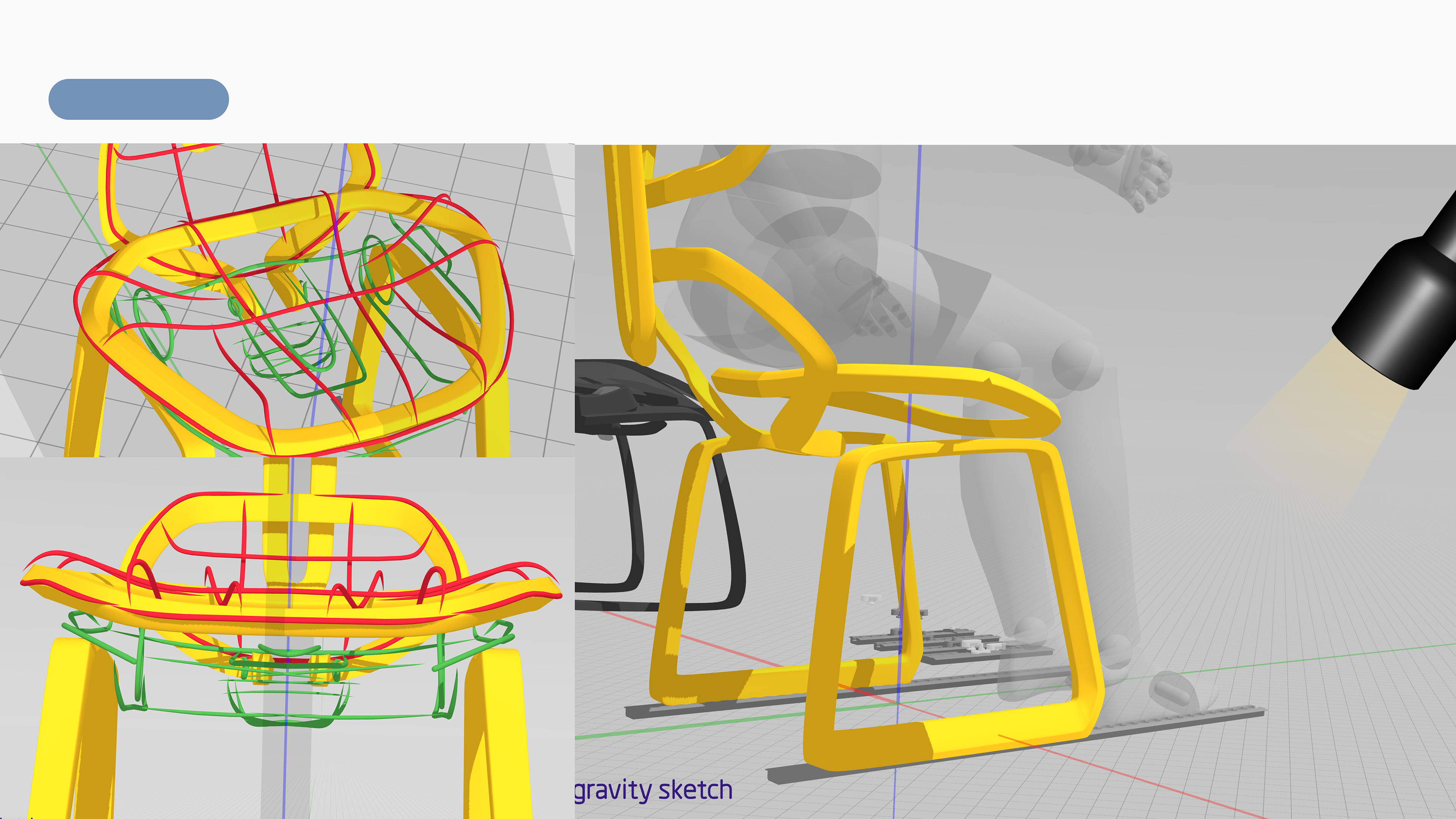

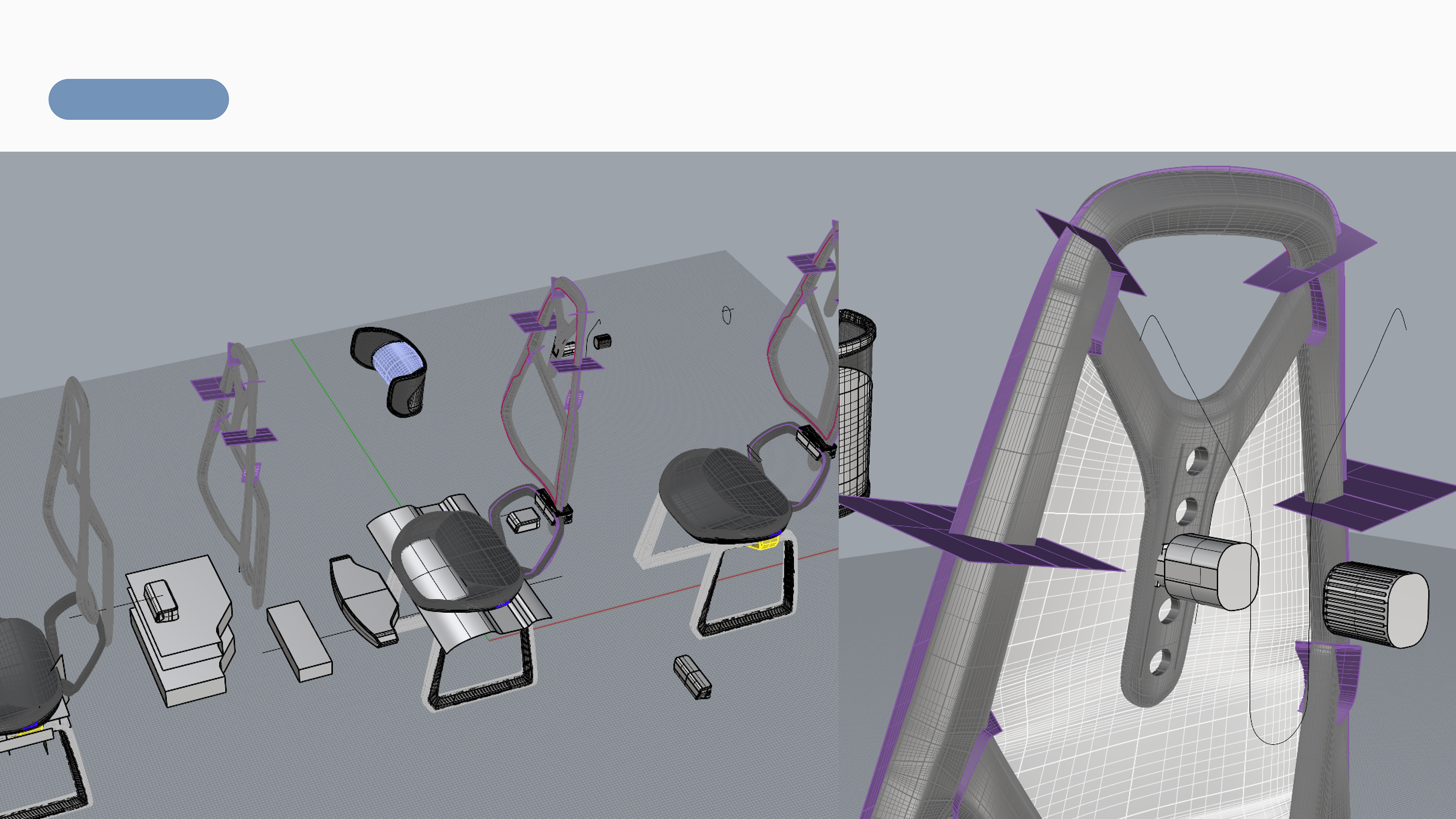

10 w I Thesis Project I Gravity Sketch / Rhino / Adobe Substance 3D / Keyshot / Photoshop

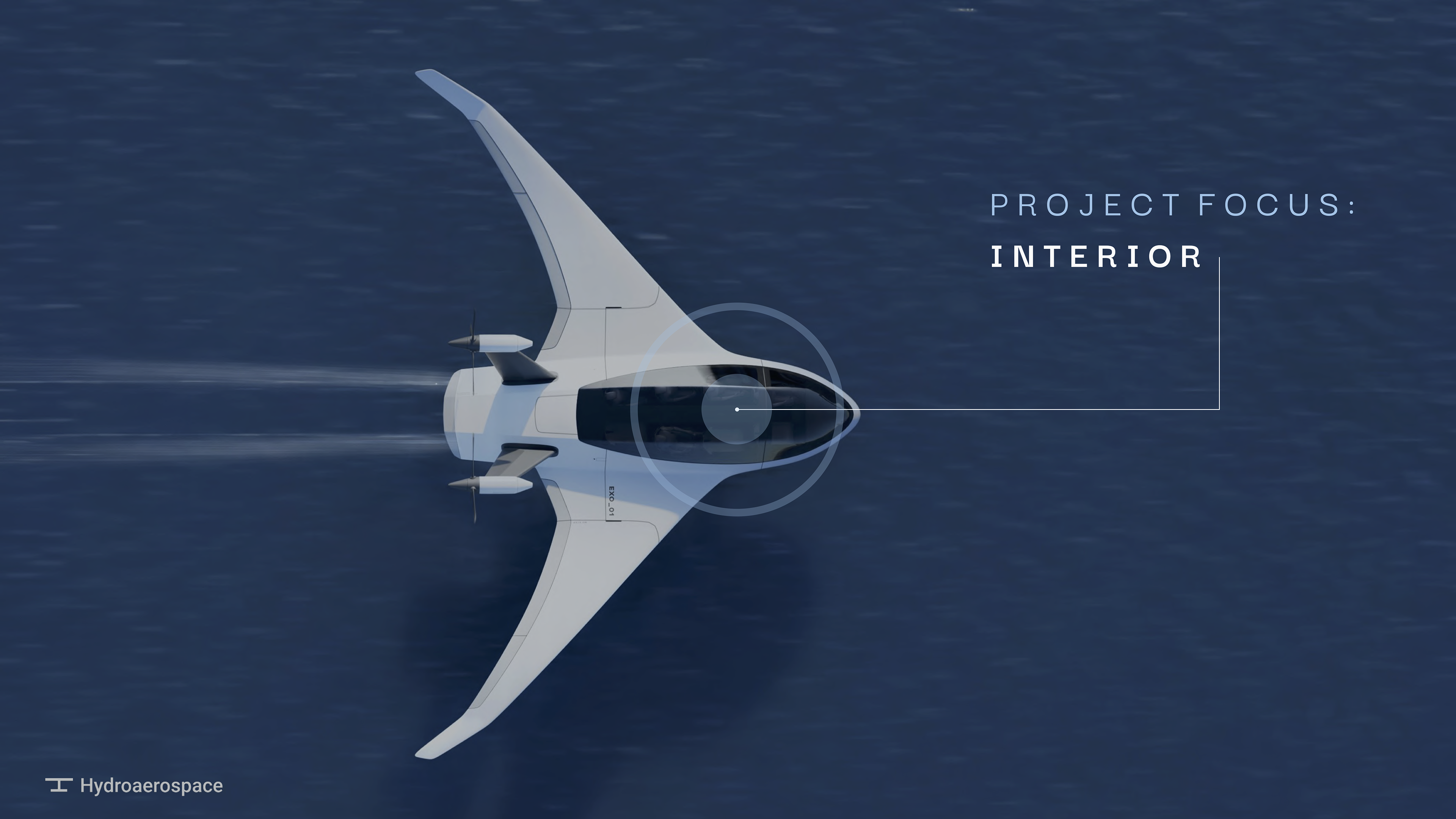

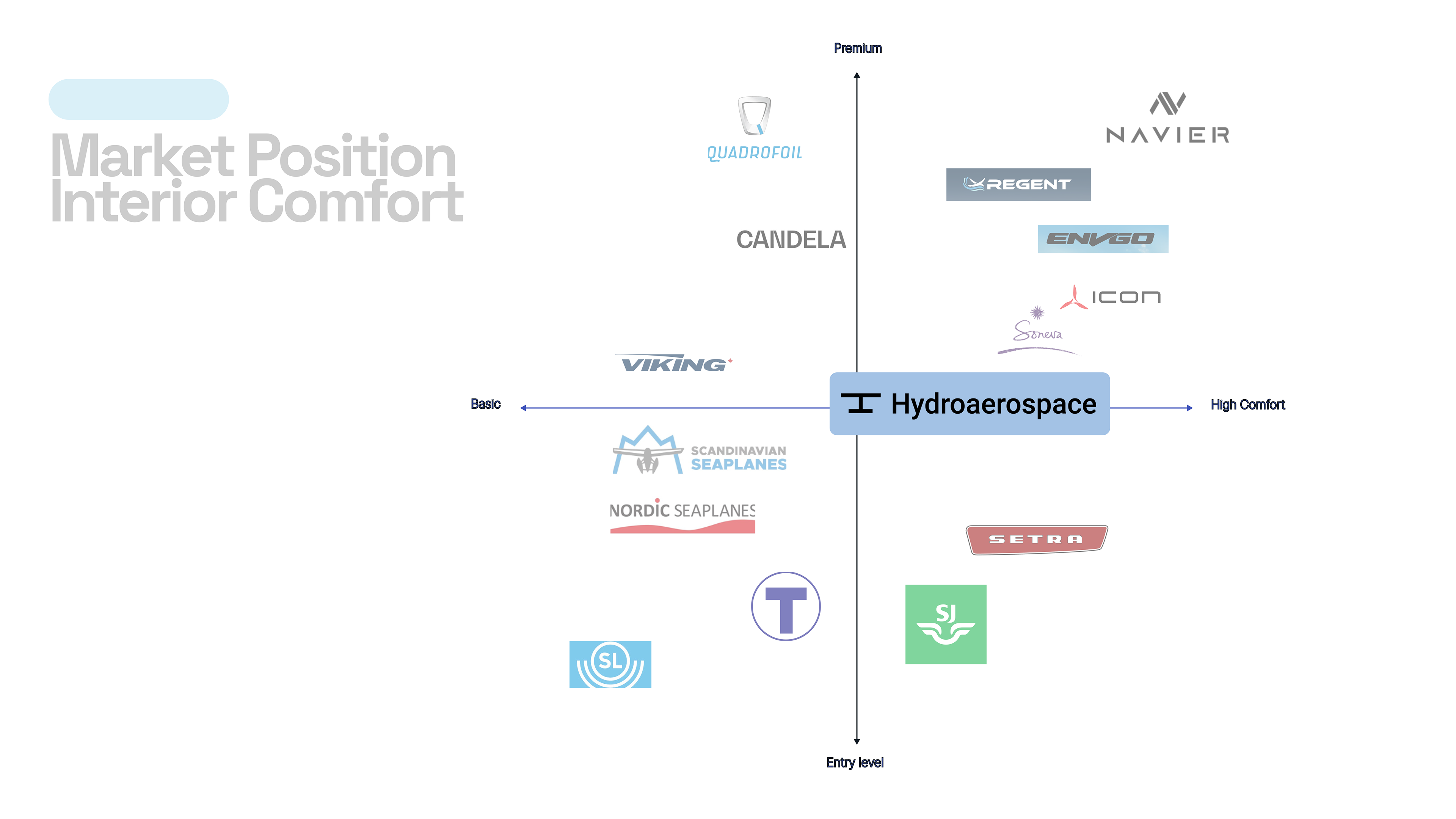

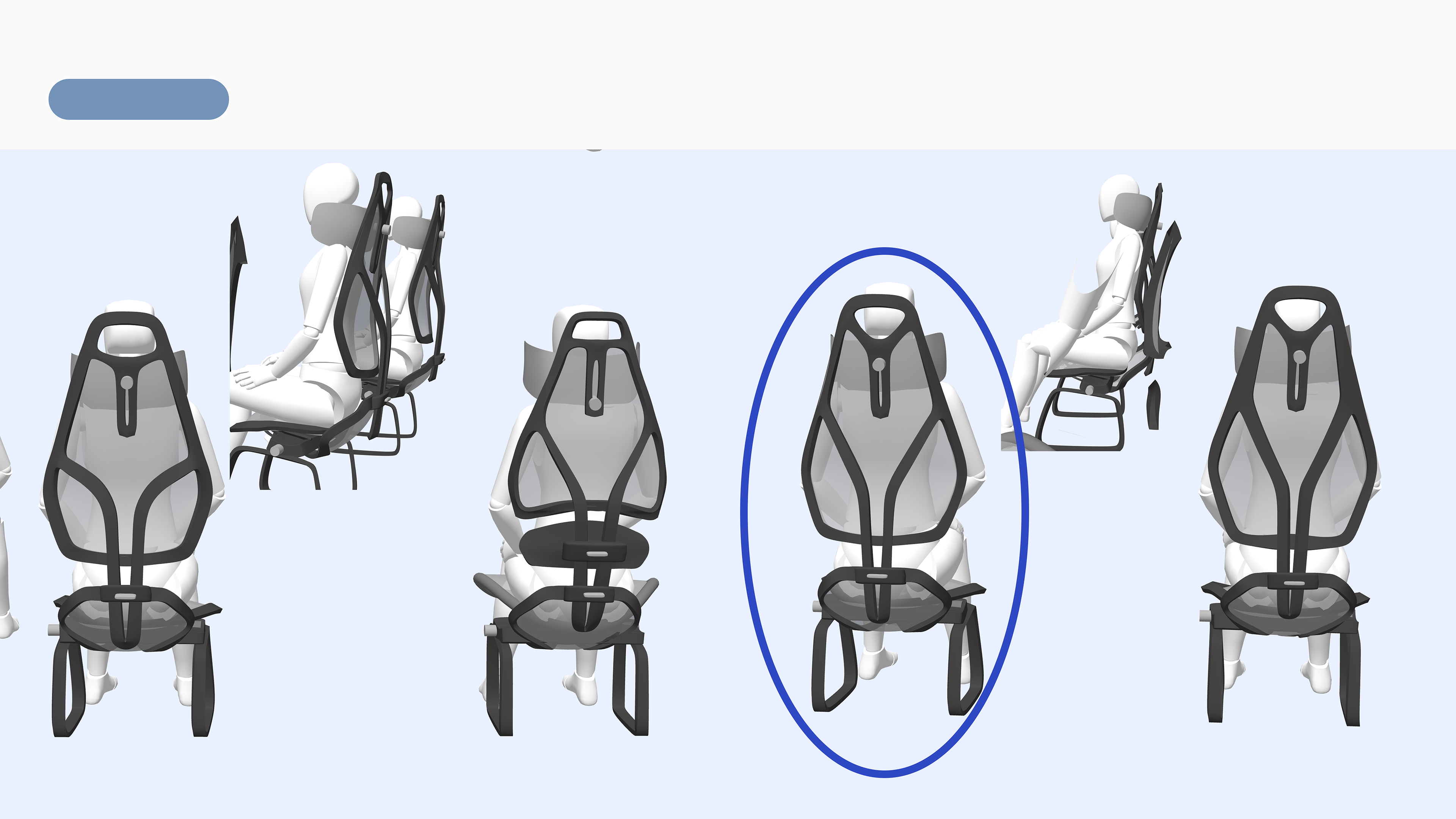

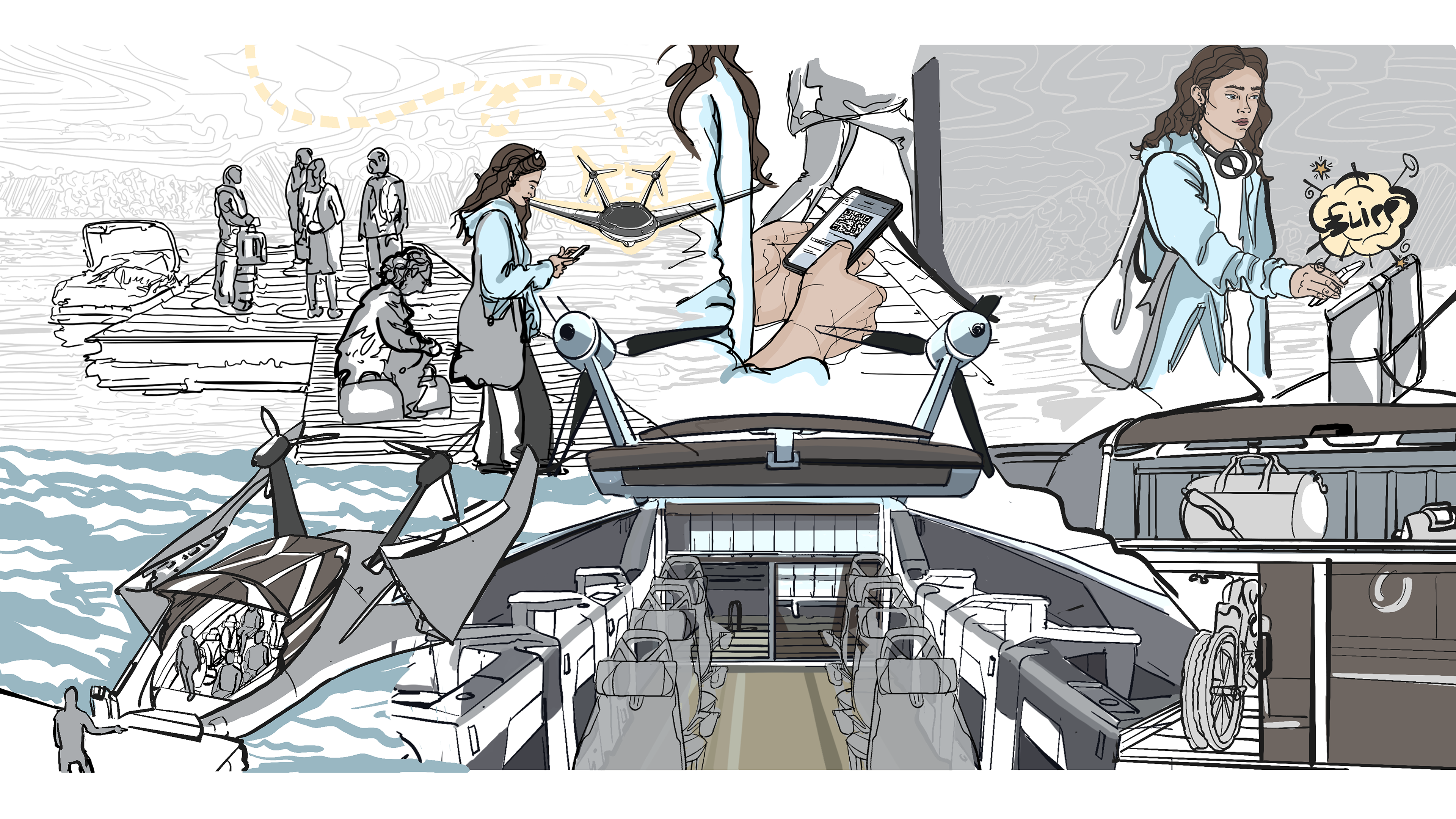

Hovvi is a design proposal for a modular, ergonomic seat and cabin interior system tailored for new commercial electric hydrofoiling seaplanes. A technology emerging as a sustainable alternative to coastal and short distance regional travel in Swedens southern areas. Developed in collaboration with Swedish startup HydroAerospace, the project explores how seaplane interiors can support ecological transition without compromising comfort, accessibility, or spatial efficiency.

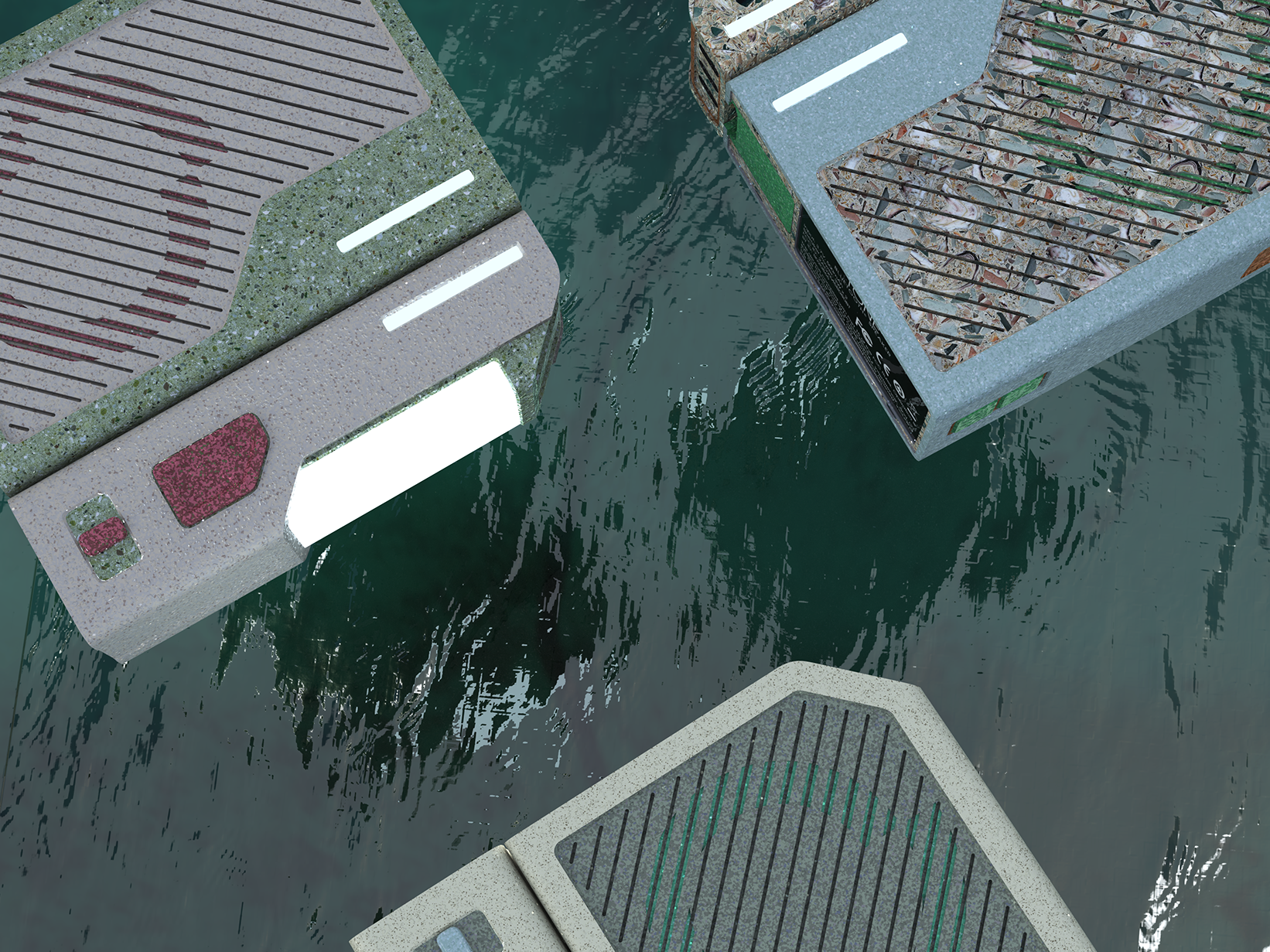

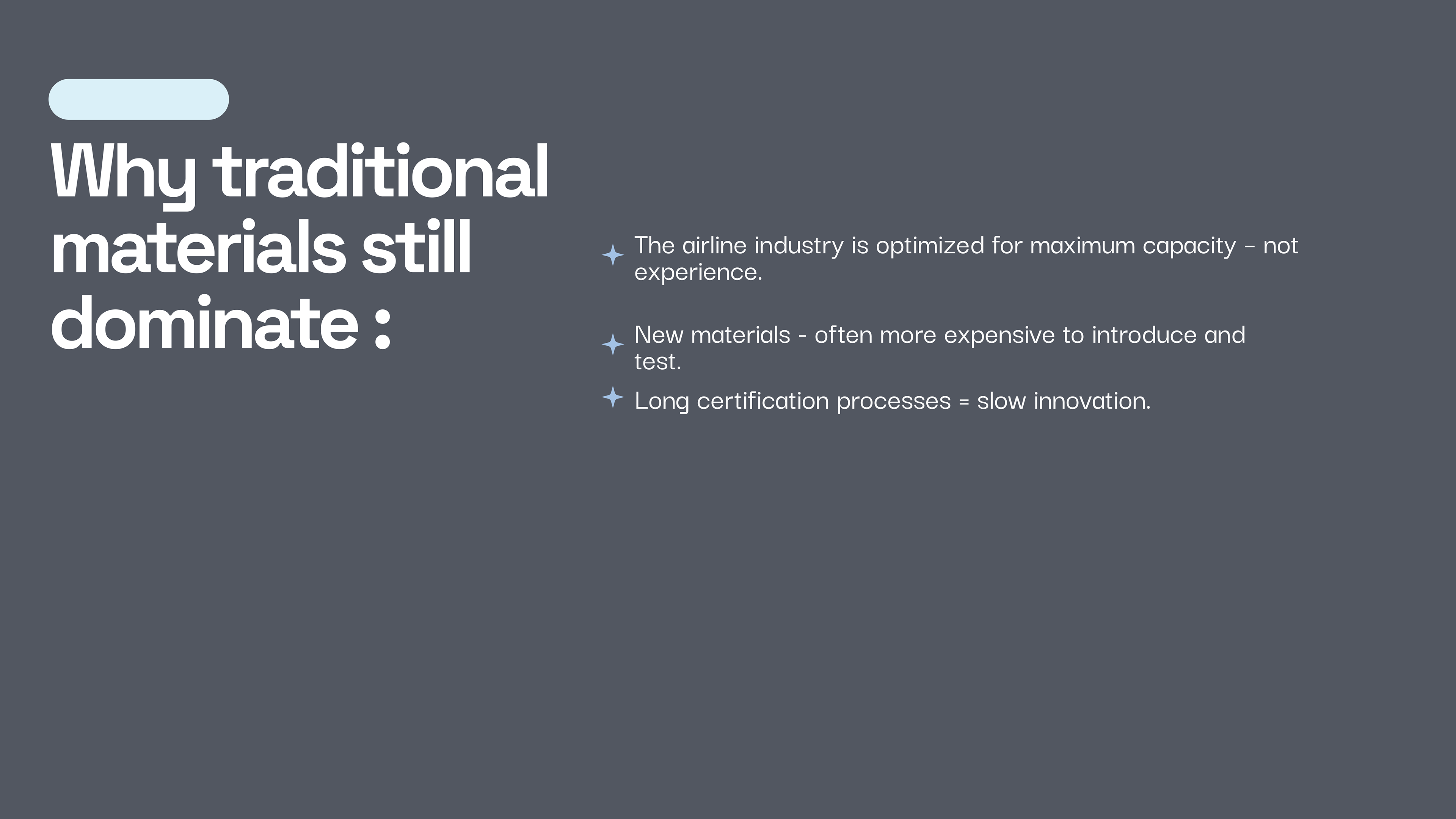

Where the automotive industry often treats Color, Material, and Finish (CMF) as an afterthought, Hovvi turns this logic on its head. Rather than applying surface treatments late in the process, materials were used as a primary driver of form and function from the outset. The design was shaped by what the materials demanded, their limitations, behaviours, and environmental profiles, allowing sustainability to become a structural and expressive part of the project, not a layer added on top. Hovvi also aims to serve as a competitive alternative to today’s emission heavy transport systems. In Sweden alone, over 21 million vehicles board ferries annually, contributing heavily to maritime emissions. A 50 km daily commute by car emits 2.1 tons of CO2 per person per year. Meanwhile, many seaplanes still use interiors that haven’t seen a functional or aesthetic update since the 1970s, relying on outdated, heavy materials that shorten flight range and increase energy consumption.

By reducing interior weight by up to 30–50%, Hovvi contributes directly to extending the electric aircraft’s range and lowering operational emissions, a critical step toward meeting aviation’s climate goals.

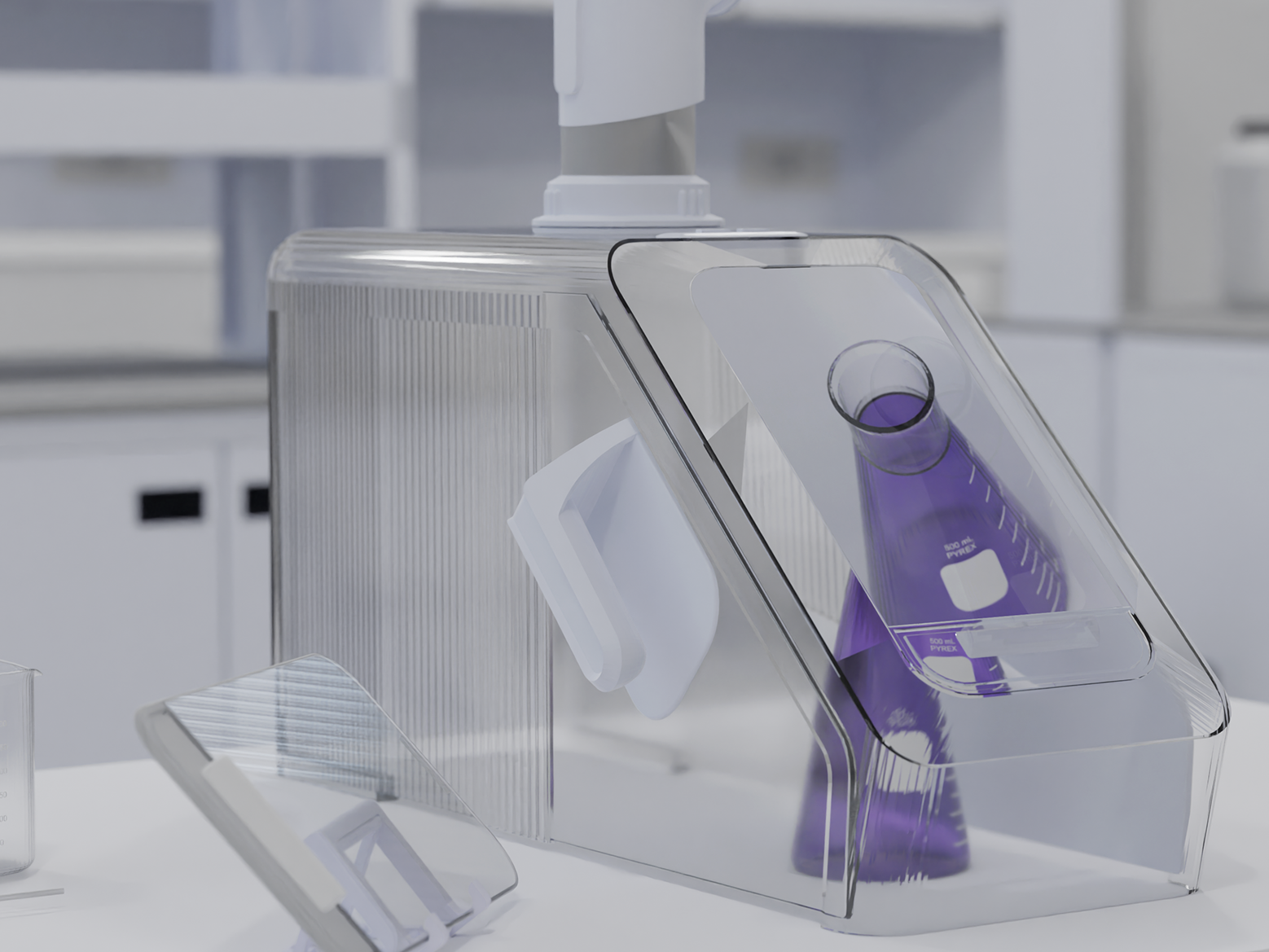

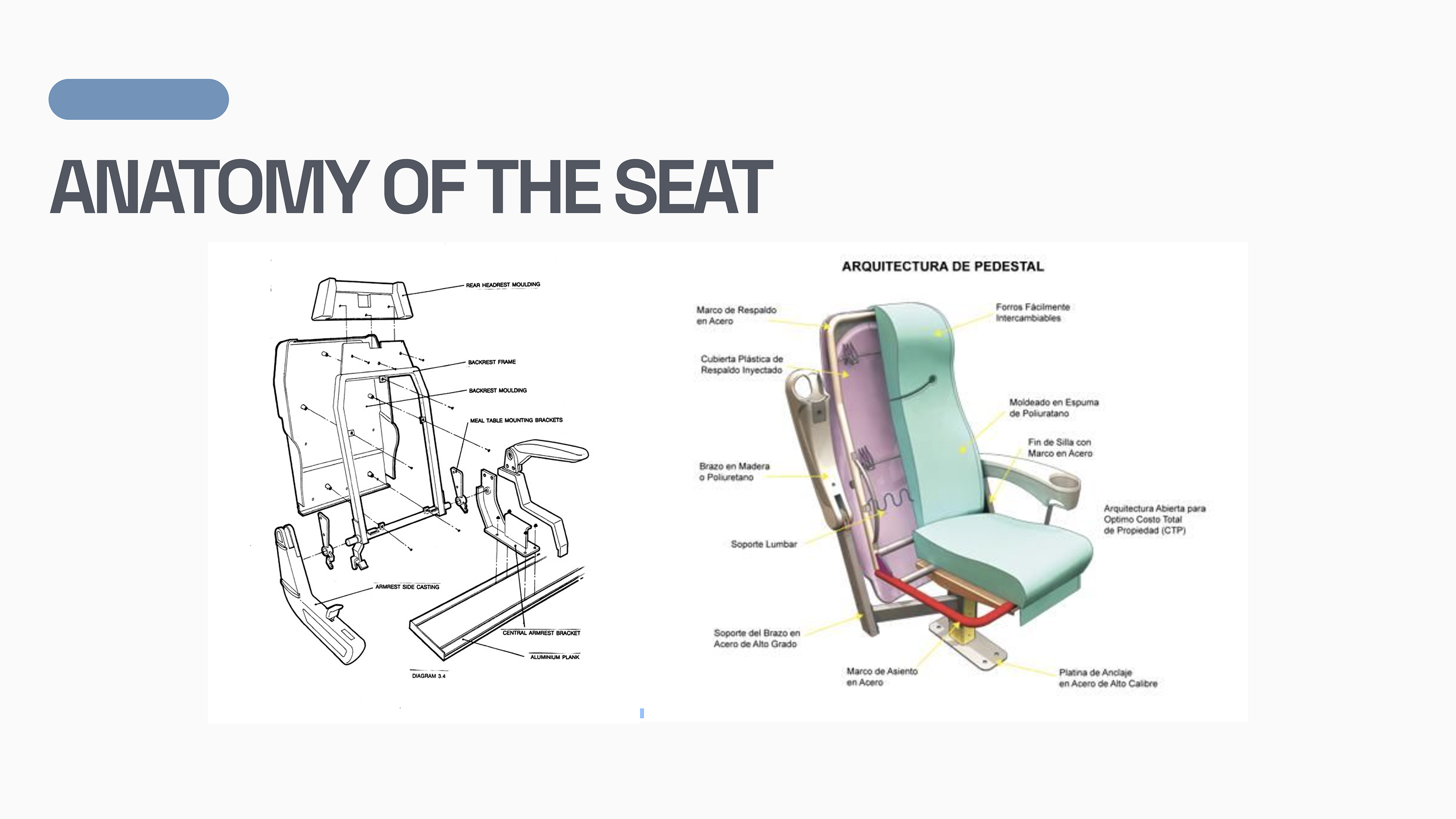

Hovvi proposes a circular material strategy, using bio-based and recycled composites such as PaperShell, Bcomp flax fibers, FSC-certified bamboo, hemp mesh, and cork/rubber flooring, all carefully selected for their weight saving, low-emission properties, and aviation potential. Materials were selected not just for ecological value but also for manufacturability and operational efficiency, reducing weight by up to 50% in key areas, which translates directly to extended electric range and lower emissions per flight. The seat is designed for disassembly, enabling components to be repaired, replaced, or recycled, in contrast to the glued, monolithic construction typical of aircraft interiors today. Every element was evaluated for its full lifecycle, ensuring that nothing is over or under-engineered.

Ultimately, Hovvi is a systems-level design that rethinks what sustainability means in aviation, not as a surface aesthetic, but as an integrated philosophy guiding every material choice, spatial decision, and user interaction.

Where the automotive industry often treats Color, Material, and Finish (CMF) as an afterthought, Hovvi turns this logic on its head. Rather than applying surface treatments late in the process, materials were used as a primary driver of form and function from the outset. The design was shaped by what the materials demanded, their limitations, behaviours, and environmental profiles, allowing sustainability to become a structural and expressive part of the project, not a layer added on top. Hovvi also aims to serve as a competitive alternative to today’s emission heavy transport systems. In Sweden alone, over 21 million vehicles board ferries annually, contributing heavily to maritime emissions. A 50 km daily commute by car emits 2.1 tons of CO2 per person per year. Meanwhile, many seaplanes still use interiors that haven’t seen a functional or aesthetic update since the 1970s, relying on outdated, heavy materials that shorten flight range and increase energy consumption.

By reducing interior weight by up to 30–50%, Hovvi contributes directly to extending the electric aircraft’s range and lowering operational emissions, a critical step toward meeting aviation’s climate goals.

Hovvi proposes a circular material strategy, using bio-based and recycled composites such as PaperShell, Bcomp flax fibers, FSC-certified bamboo, hemp mesh, and cork/rubber flooring, all carefully selected for their weight saving, low-emission properties, and aviation potential. Materials were selected not just for ecological value but also for manufacturability and operational efficiency, reducing weight by up to 50% in key areas, which translates directly to extended electric range and lower emissions per flight. The seat is designed for disassembly, enabling components to be repaired, replaced, or recycled, in contrast to the glued, monolithic construction typical of aircraft interiors today. Every element was evaluated for its full lifecycle, ensuring that nothing is over or under-engineered.

Ultimately, Hovvi is a systems-level design that rethinks what sustainability means in aviation, not as a surface aesthetic, but as an integrated philosophy guiding every material choice, spatial decision, and user interaction.

Exterior of Seaplane

Hydrofoiling Technology

Project Focus

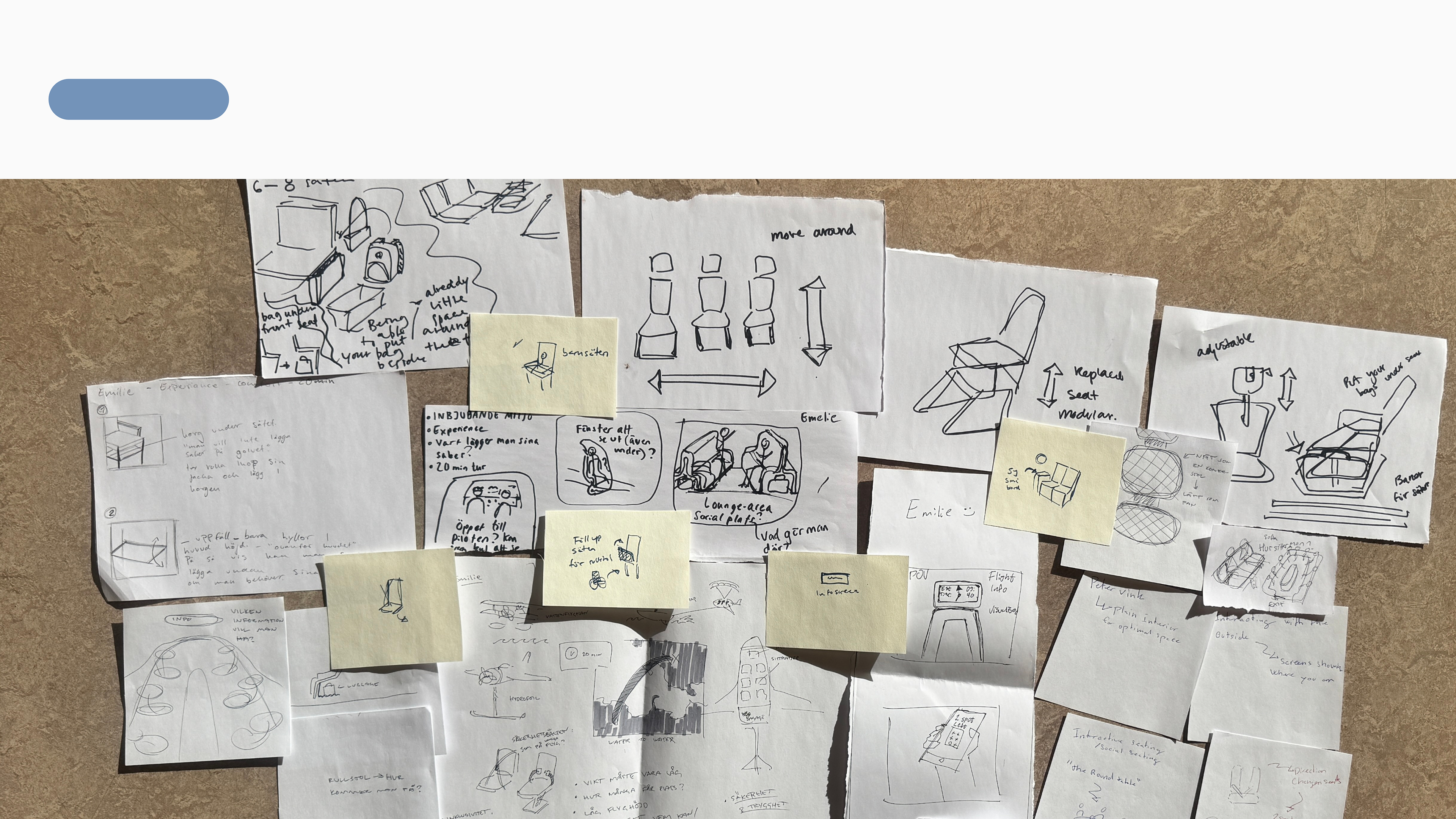

D I S C O V E R

D E F I N E

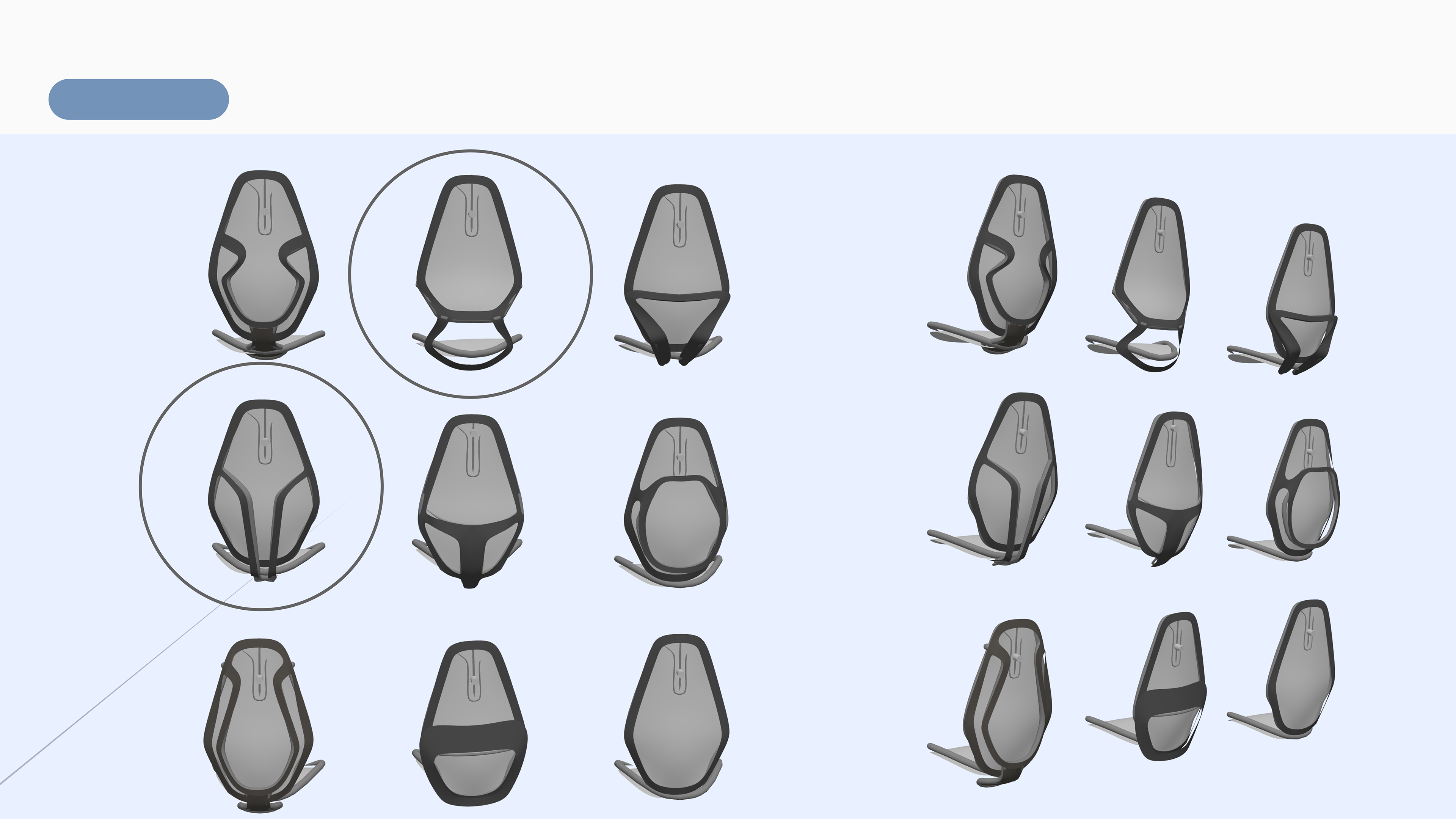

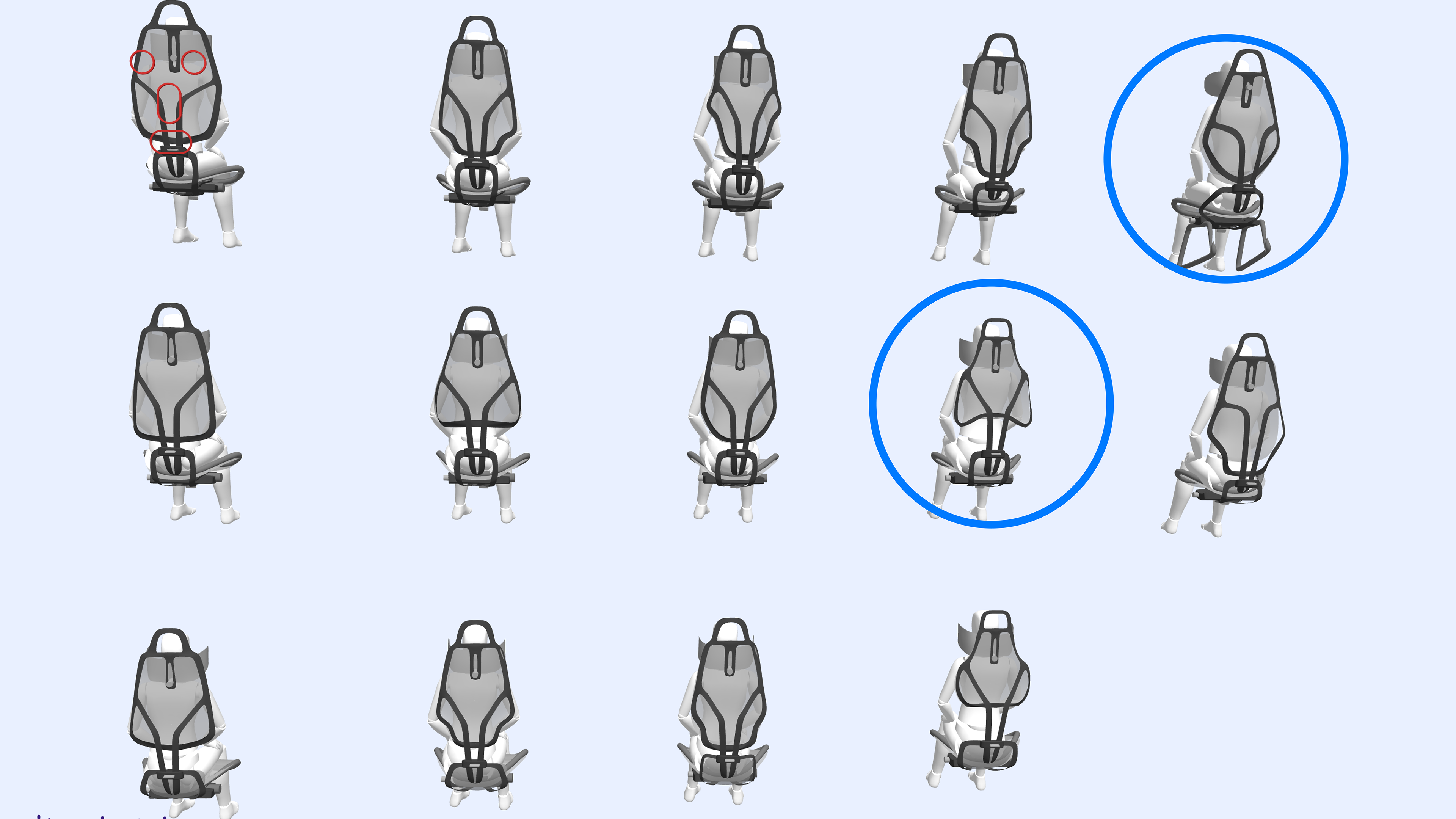

D E V E L O P

M O D E L M A K I N G P R O C E S S

D E L I V E R

L-Track System

Larger Cargo Compartment

Slide-Door

Emergency Utility's

U S E R S C E N A R I O

UID TALKS - JUNE 2025

Material Tray

1:4 Model

P I T C H V I D E O